News

The future in the view

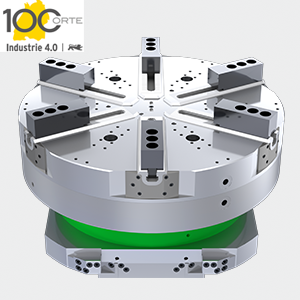

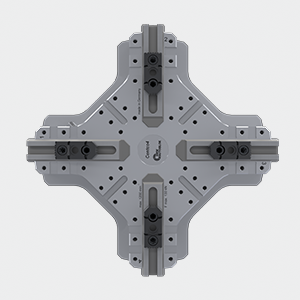

RT e-motion

RT e-motion:

Electro-mechanical tombstone

with integrated drives

Electro-mechanical tombstone

with integrated drives

- Each clamping device can be controlled individually

- Wireless transmission of energy and data via induvtive coupler system

- Clamping station can be equipped individually

- Permanent monitoring of the clamping force and clamping positions

- Various strokes and forces individually programmable

- Plug & Play

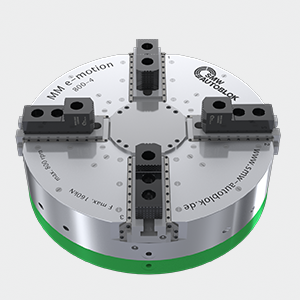

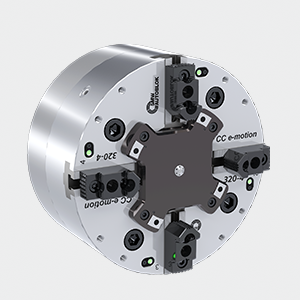

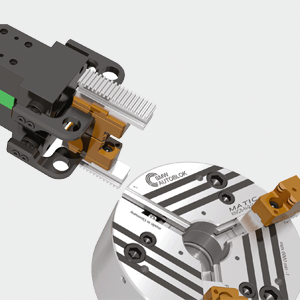

MM e-motion

MM e-motion:

Electro-mechanical

universal 4-jaw chuck

Electro-mechanical

universal 4-jaw chuck

- Each jaw driven and controlled via e-motor

- Wireless transfer of power and sensoric via inductive coupler

- Clamping of any shape workpieces

- Automatic adjustment of the center line

- Constant monitoring of the clamping force and the clamping position while rotation

- Sealed and low maintenance

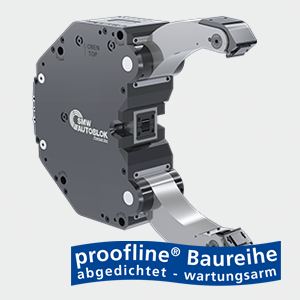

F500 e-motion

Received an award for Industry 4.0:

F500 e-motion:

Electro-mechanical

actuation flange

F500 e-motion:

Electro-mechanical

actuation flange

- For actuation of standard power chucks on millturn centers

- Wireless transfer of power and sensoric via inductive coupler

- Electric driven

- Safety systems – electronical and mechanical

- Bidirectional linear regulation of clamping force

- Sealed and low maintenance

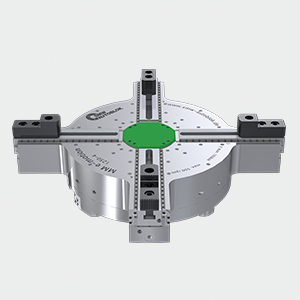

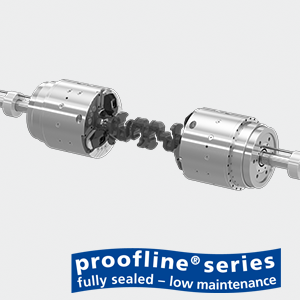

Inductive Couplers

Inductive Couplers:

Inductive power- and data transmission

■ For mechatronic workholding,

handling systems and robotic

■ Power transmission up to 1800 W

■ Signal- and BUS transmission

■ Protected according to IP 67

■ Different versions and sizes available

Inductive power- and data transmission

■ For mechatronic workholding,

handling systems and robotic

■ Power transmission up to 1800 W

■ Signal- and BUS transmission

■ Protected according to IP 67

■ Different versions and sizes available

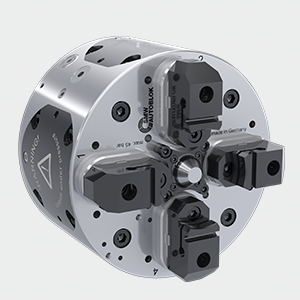

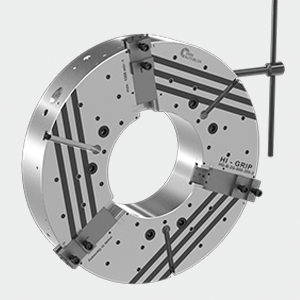

CSC

CSC:

Crank shaft chuck with retractable jaws

Crank shaft chuck with retractable jaws

- Self centering or compensating clamping

- Quick and safe automatic loading of the crank shaft because of retractabale jaws and centers

- Highest chip removal because of integrated hydraulic locking system

- Maximum machine availability because oil bath lubricated

- Fully sealed and low maintenance